ترجمه فارسی عنوان مقاله

اصلاح روند مشخصات ادغام سایت حرارت کل برای کاهش هزینه سرمایه

عنوان انگلیسی

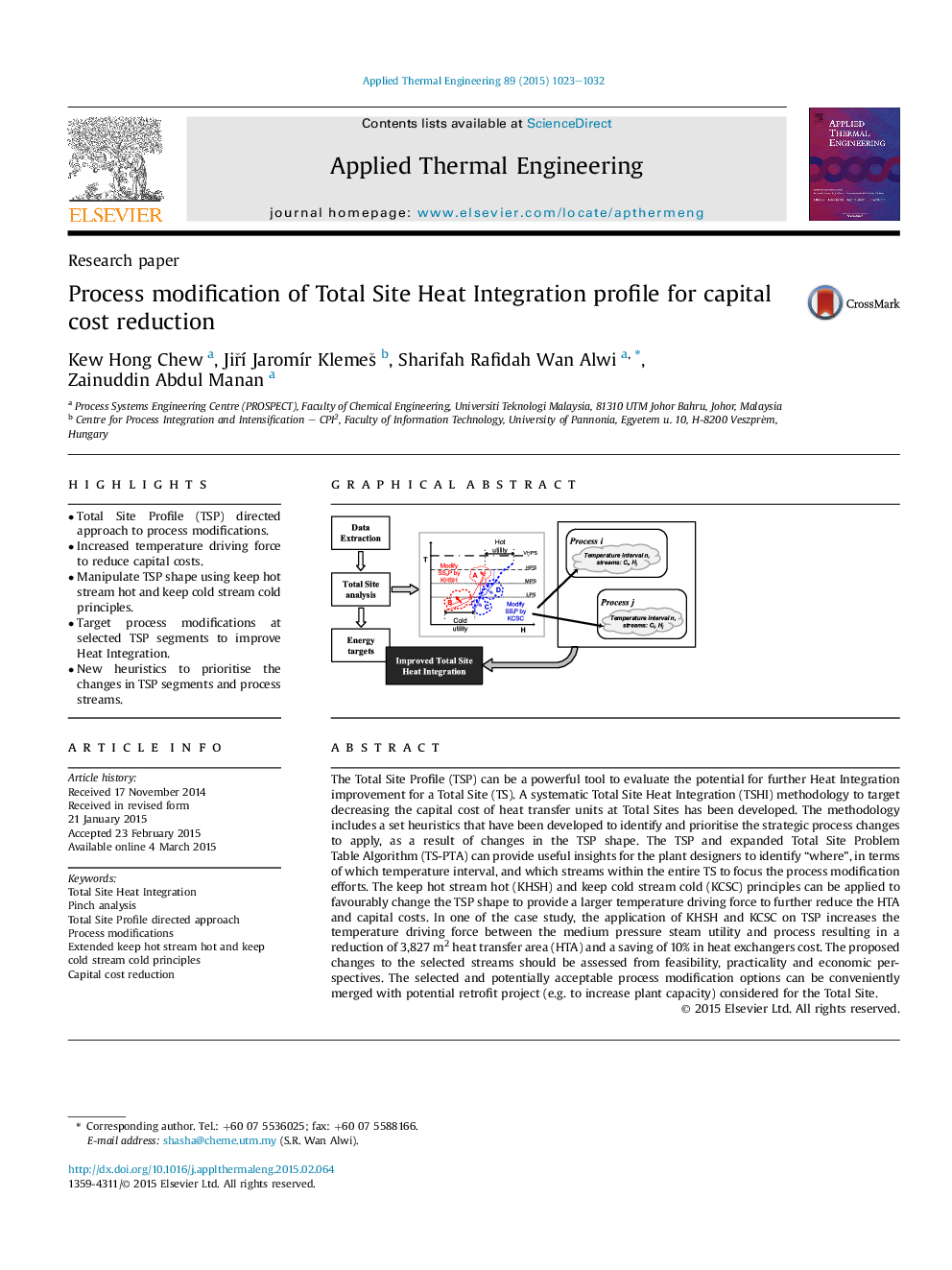

Process modification of Total Site Heat Integration profile for capital cost reduction

| کد مقاله | سال انتشار | تعداد صفحات مقاله انگلیسی |

|---|---|---|

| 50465 | 2015 | 10 صفحه PDF |

منبع

Publisher : Elsevier - Science Direct (الزویر - ساینس دایرکت)

Journal : Applied Thermal Engineering, Volume 89, 5 October 2015, Pages 1023–1032

ترجمه کلمات کلیدی

ادغام سایت حرارت کل - تجزیه و تحلیل خرج کردن - تغییرات روند - کاهش هزینه سرمایه

کلمات کلیدی انگلیسی

Total Site Heat Integration; Pinch analysis; Total Site Profile directed approach; Process modifications; Extended keep hot stream hot and keep cold stream cold principles; Capital cost reduction